New Lanark

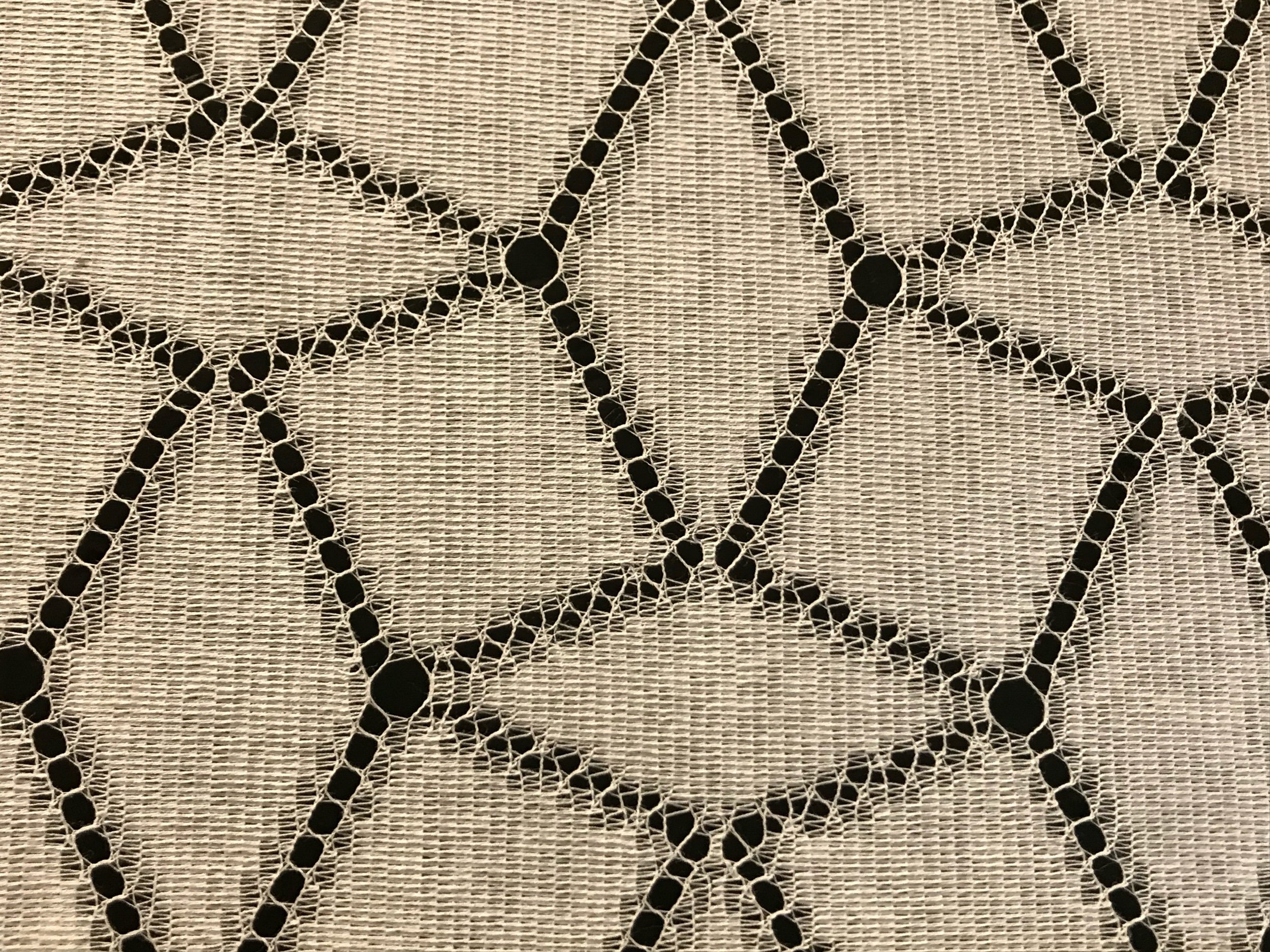

Day 5. Thursday, May 12, 2022: We head west to New Milns to MYB Textiles, the last Scottish lace mill. Founded in 1900, it is the final remaining mill in Ayrshire. MYB manufactures patterned lace on original Nottingham Lace Looms as well as clipped Madras sheer fabric; MYB is the only producer in the world for both. The mill is a mixture of old and new technology. The Nottingham Lace Looms are mostly analog, running on punch cards, although some have been networked into computers in the design office. The Nottingham looms are VERY different technology from what most weavers are familiar with. Each loom has hundreds or thousands of shuttles which are small discs wound with thread, oriented perpendicular to the fabric. The discs pass back and forth, wrapping around warp threads. The looms have a very distinctive and pleasant melody.

Madras lace is woven on looms which combine shafts (background) with jacquard thread control (pattern). The fabric as it leaves the loom has huge floats. The cloth is put through a machine which draws up the floats with air pressure and clips them off.

While the Nottingham lace looms produce a high-quality fabric, there are inevitable mistakes in each run. We are amazed at the ability of the darners to make invisible repairs.

Watch for the video of two men re-threading a loom. Amazing how fast they work! Look closely for punch cards feeding through the dobby at the top of a lace loom, and a side view showing how the shuttles pass back and forth, wrapping around the warp threads.

MYB has a loom that is 40’ (yes, feet) wide, which is by far the biggest loom we have ever seen. This loom is commonly used to weave scrim fabric for theater backdrops. The theater and film industry is one of MYB largest customers.

We head back east a bit to the New Lanark World Heritage Site located in the spectacular Clyde Valley. Andy Cuthbertson, the heritage director, gave us a great tour. The old mill buildings are impressive, and the setting on the River Clyde is just gorgeous. There is a working spinning mule and plying machine, but no operating looms. We learn a lot of history, including how New Lanark had a fairly progressive model with education and healthcare available to all. One of the unintended consequences of Brexit becomes clear when Andy explains that the site used to receive significant funding from the EU, but now has a severe funding gap post-Brexit that has not been addressed by the British government.

On the way to the hotel, we spot the first hairy coos of the trip!